Mill results

Chemical mixing efficiency in figures

Based on the mill results of more than 650 supplied mixing stations, chemical consumption reduces by 20-60% on average, water consumption in post dilution – by 100%. Optimal chemical mixing location improves the runnability and stability of the process, and makes wet end chemistry easier to control.

Mill results

SAPPI Stockstadt Mill, PM1, Germany

“We got better machine total efficiency, and reduced chemical, energy and water consumption…”

- 91% fresh water savings

- 69% lower energy consumption

- 18% lower chemical demand

- 65% less time is lost due to specific breaks

Mitsubishi Paper Mills, PM7 in Hachinohe mill, Japan

“A great reduction in production costs and increase in productivity”

- 39% reduction of retention aids

- 3,5% production increase

- 33% extended shut-down cycle

- 33% prolonged lifetime of felts and wires

NewPage Wisconsin Rapids, PM16, USA

“The rapid and thorough mixing had an instant impact on performance.”

- 43% savings of retention aid silica

- 33% savings of retention aid polymer

- 300 000 m³/a fresh water savings

- 14 650 MWh/a energy savings

- 5% increased filler content of sheet

- 8% increase of reel speed

Sun Paper Honghe, PM31 and PM32, China

Excellent results followed by new repeat orders

- 1 m3/ton of paper fresh water savings

- 30-100% chemical savings

- Excellent runnability

- Better formation

- Good product characteristics: low basis weight, high strength, good folding resistance, high ring crush strength

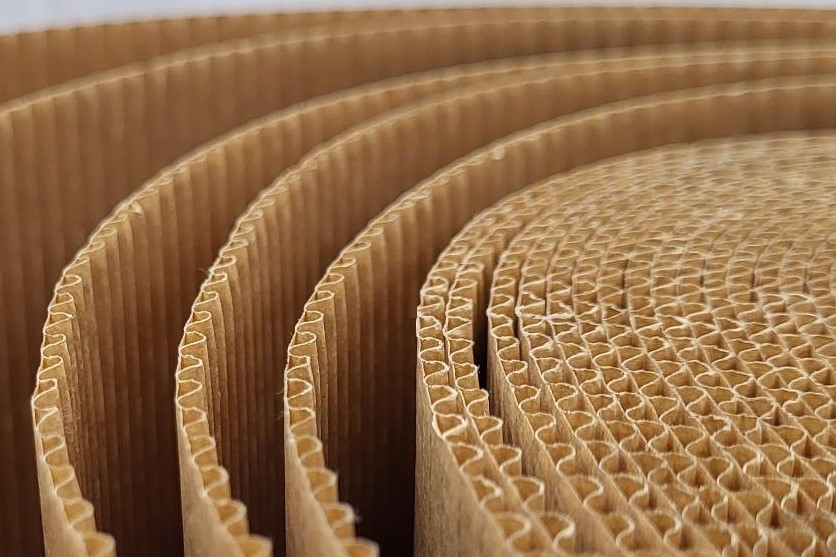

Linerboard and corrugated medium production line, Russia

100% retention aid polymer savings and fresh water savings

- 100% retention aid polymer savings

- Starch operates both as strength agent and retention aid

- 15-20% strength starch savings

- 10% AKD savings

- Fresh water is no longer needed for chemical post-dilution

Folding boxboard board line, Europe

Better performance and reduced consumption

- 25-35% starch savings

- Other chemicals: positive development in performance and savings in consumption

- Better formation

- Fresh water savings

- Several eductor systems replaced in/removed from all the plies

Folding boxboard and liquid packaging board line, China

TrumpJet® Flash Mixing Reactor gives a massive boost to efficiency and sustainability

- 20-50% chemical savings

- Better formation

- 10-20% increase of machine speed

- 1,8 mill m3/a fresh water saving

- 80000 MWh/a energy saving

Liquid packaging board line, Western Europe

Reduced bacteria growth with less biocide chemical

- More efficient chemical mixing

- Improved biological growth control

- Reduced consumption of biocide chemical

- Disappearance of biocide smell in the stock preparation area

- Injection with white water

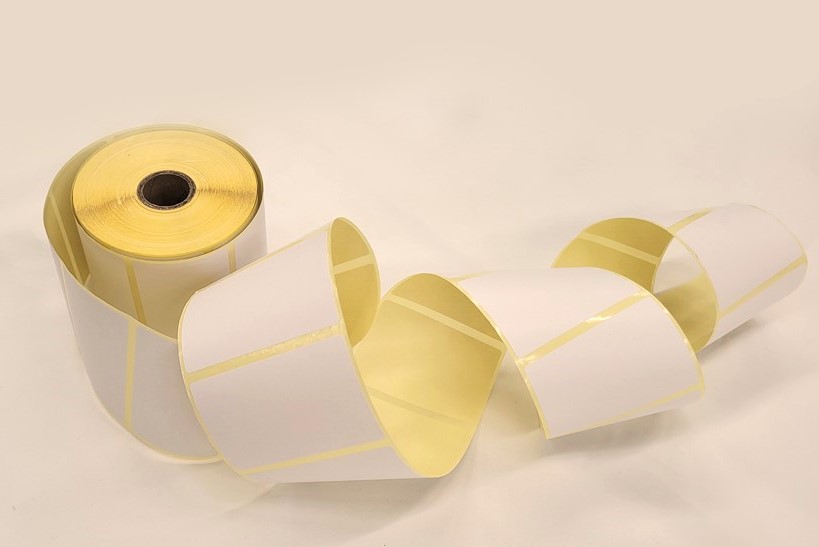

Label paper line, Europe

Zero water consumption and significant improvement in retention

- No fresh water used. Chemical injection with headbox stock.

- Improved retention and retention control

- 10-15% retention aid savings

- 25-40% reduced consumption of sizing agents (50% for AKD)

- 8% reel speed increase

Release paper line, Europe

Fresh water savings, reduced chemical demand, higher quality

- 360 m3/day fresh water savings

- 10-20 m/min machine speed increase

- 20% improved formation

- 20-30% lower polymer consumption

- 10-20% ASA savings, improved retention of ASA, more uniform sizing

Label paper machine, China

30-Day Investment Return

- 20% retention aid APAM savings

- 20% retention aid Silica savings

- 20% sizing agent AKD savings

- 20% sizing agent PAE savings

- Good paper quality and production runnability

- The usage of fresh water or filtrate for chemical mixing is eliminated

- 30 days payback time of the investment

Pulp mill, Finland

White liquor oxidation

“TrumpJet Flash Mixing improves efficiency of oxidation in the white liquor vessel.

It works very well. Surprisingly good and simple solution with no need for the conventional reactor.”

DIP/Newsprint, UK

Dissolved air flotation

TrumpJet® Flash Mixing in a tertiary clarifier improves efficiency

- Efficient flash mixing of additives

- Dissolved air injected through TrumpJet mixers

- Micro air bubbles (< 50 µm) can also be generated

Mill fresh water system, Finland

Water treatment

TrumpJet® put an end to the complaints of the water user

- Better chemical mixing improved system operation

- Stable pH, less variations

- Removal of organic solids: before 65%, after 75%

Release paper mill, Europe

Defoaming

Defoamer agent mixing into a wire pit.

- Improved chemical mixing

- 50% chemical savings

- Foam build-up and gas volume in

control - No chemical overdosing

- Improved response to control

- Improved cleanliness

- Injection with circulated white water

DIP/Newsprint, Northern Europe

Sludge dewatering

- Zero fresh water consumption for chemical mixing

- 35% polymer savings

- Operation became stable and homogenous

- Good, much improved runnability

- No unscheduled service is needed any more

- Consistency after gravity table increased 1…2%

- Total system capacity increase

Pulp and paper mill, Finland

Sludge dewatering

- Injection of polymer using sludge with TrumpJet Trombone

- Automated self-cleaning mechanism; most suitable for applications where there are obstructive particles in the injection stock.

- Superb runnability

Our clients:

Your challenge?

We have solutions.

Would you like to know more about our products and services?

Do you have a question that you would like to discuss with our experts?

We are here to help you.

Contact us

sales @wetend.com

or

Jussi Matula

CEO, Sales

Tel. +358 10 836 0108

Mobile: +358 50 303 3755

jussi.matula @wetend.com

or

Leave us a message

We will do our best to answer you within a business day.

Wetend respects your privacy. We use the personal data you have provided to us only to contact you in relation to your request.

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.

Would you like to know more about our products and services?

Do you have a question that you would like to discuss with our experts?

We are here to help you.

Contact us

sales @wetend.com

or

Jussi Matula

CEO, Sales

Tel. +358 10 836 0108

Mobile: +358 50 303 3755

jussi.matula @wetend.com

or

Leave us a message

We will do our best to answer you within a business day.

Wetend respects your privacy. We use the personal data you have provided to us only to contact you in relation to your request.