SAPPI Stockstadt Mill, PM1, Germany

“We got better machine total efficiency, and reduced chemical, energy and water consumption”

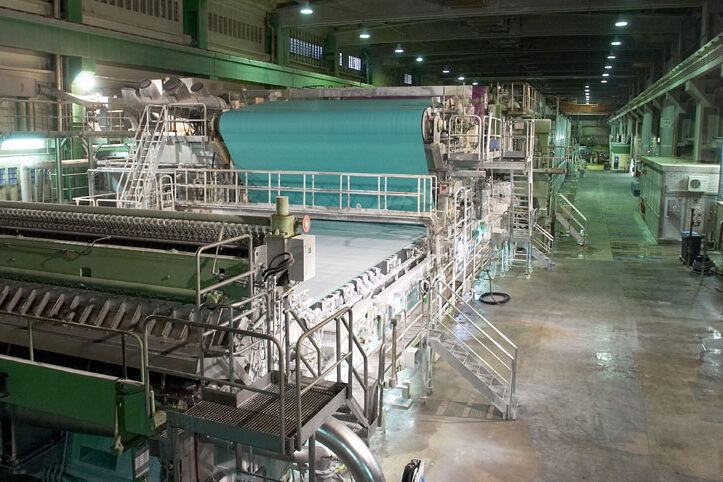

Paper machine

- Grades: Fine paper and specialty grades, coated and uncoated wood-free paper

- Production: 622 tons per day

- Production speed: 900 m/min

Objectives

- to increase the output, the efficiency of PM1

- to eliminate the substantial fresh water consumption of the standard dosing system

- to reduce chemical consumption

- to remove small unused headbox feed pipe connections, which are a potential system for dirt pockets

Our solutions

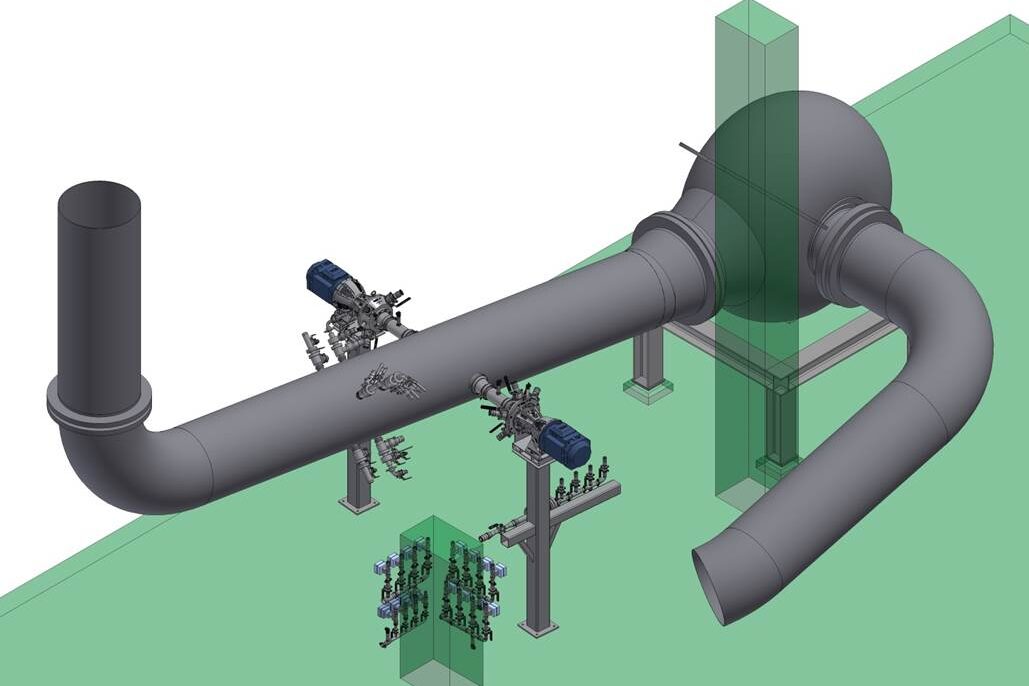

- TrumpJet Flash Mixing Reactor systems for CPAM, ASA, starch, and microparticles

- TrumpJet Flash Mixing station for defoaming agent for white water

- Web Break Eliminators were installed to remove unused pipe connections

Results of the chemical optimization project

- Total machine efficiency improved.

- Significant reduction of sheet breaks and dirt agglomerates

- Positive impact on paper formation and sheet structure

91%

reduction of fresh water usage

69%

lower energy consumption

18%

lower chemical demand

65%

less time is lost for specific breaks

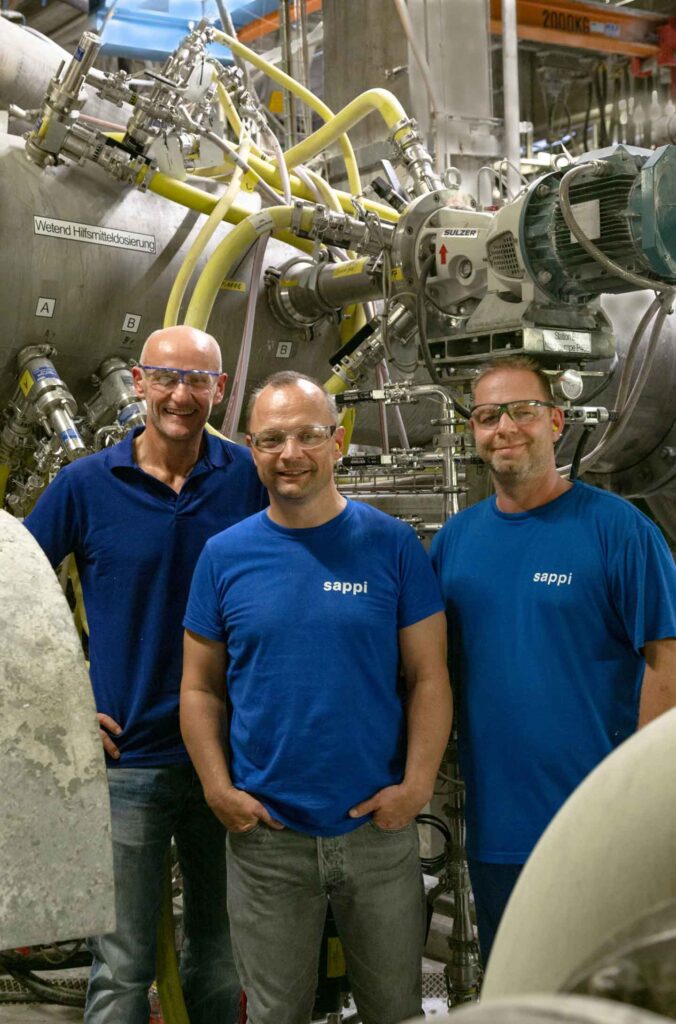

“We got excellent results with the TrumpJet Flash Mixing of chemicals… We got better machine total efficiency, and reduced chemical, energy and water consumption. Good mixing and reduced optimal chemical flow impacts positively on the paper formation and paper structure..”

Hartmut Schreck, Production Engineer at Stockstadt Mill, Sappi Europe

“I think Hartmut made a very good job in making comparison with different dosing and mixing systems from other companies… We are learning each day with our good process because there are always new positive impacts.”

Jochen Hahn, Manager Production Line 1 at Stockstadt Mill, Sappi Europe

See more mill results here.