Defoaming

TrumpJet Mixing of Defoamer

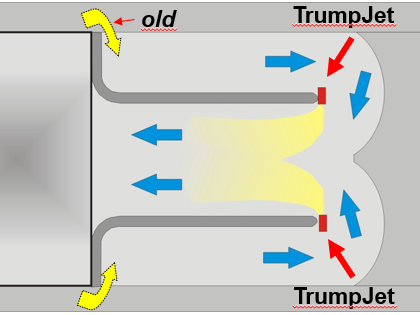

The good mixing of defoaming agent is vital for effective removal of excessive entrained air from white water and for the prevention of foam build-up. TrumpJet Poco for defoaming agents optimizes the usage of additives and significantly reduces consumption. It guarantees effective foam control, a cleaner and more stable process with less dirt deposits in the process and on fabrics.

Benefits of TrumpJet Flash Mixing for Defoamer

Effective foam control

- prevention of foam build-up

- removal of entrained air

- stable process

Reduced consumption

- cost savings up to 50%

- lower dosage of defoamer

- optimal or better use of all additives

Process cleanliness

- reduced dirt and deposits

- cleaner fabrics

- fewer defects

Increase the efficiency of defoamer by fast and homogeneous mixing

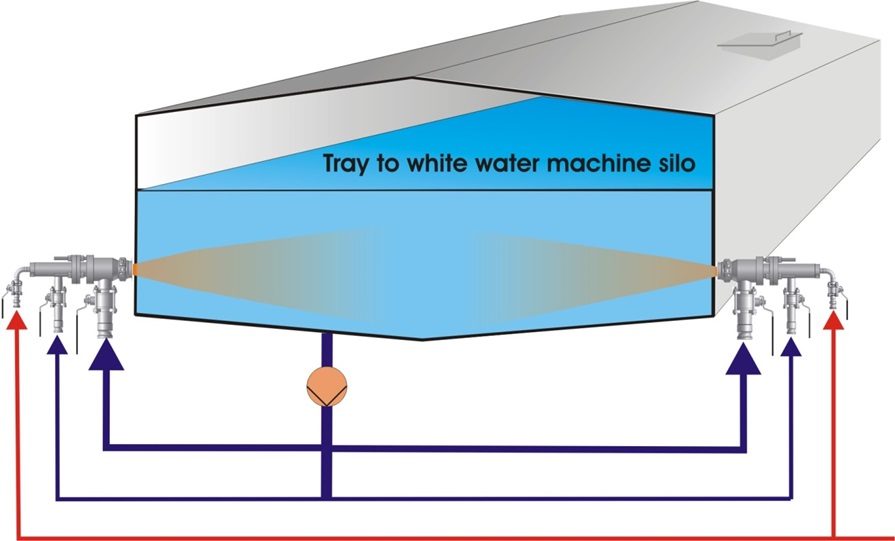

The uniform distribution of defoaming agent throughout white water plays a pivotal role for its effect.

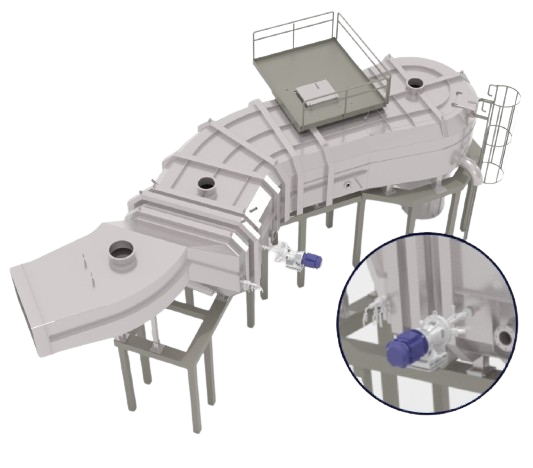

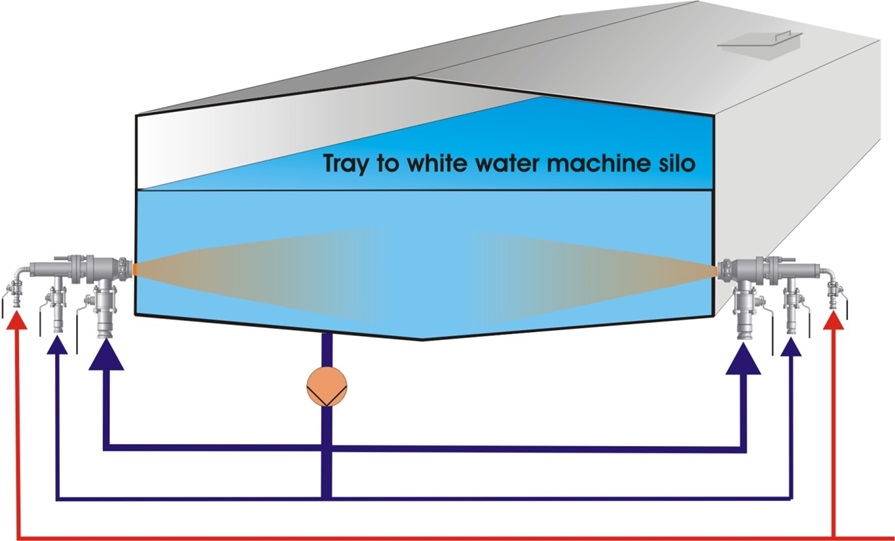

The mixer TrumpJet Poco is specially designed to mix very small chemical flows into large process streams. It guarantees homogeneous distribution of the defoamer, which is usually so small in volume that it is difficult to mix properly with conventional methods. No need to wait for the process tray water to make a complete loop/circulation for a decent effect.

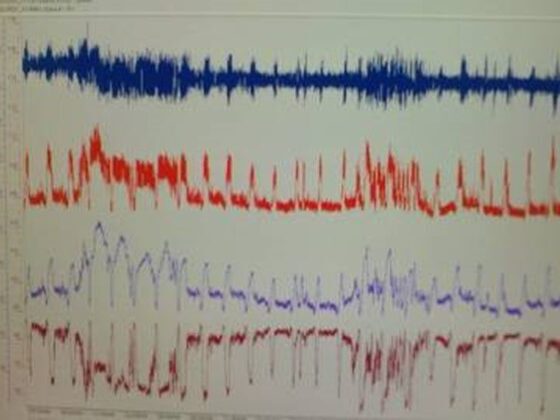

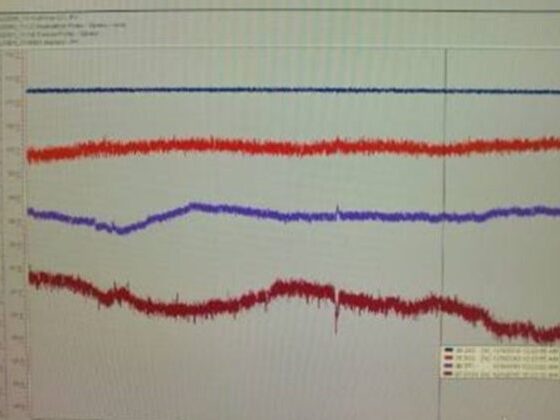

With TrumpJet Flash Mixing for defoamer, the process is stable and the entrained air and foam are in control.

Reduce defoamer consumption by half and avoid the adverse effects of overdosing

Good mixing and flow homogeneity significantly improve the performance of defoamer, allowing the desired effect to be achieved with a considerable reduction in consumption, often about 50%.

By enabling much lower defoamer consumption, TrumpJet easily prevents numerous runnability and quality issues caused by severe overdosing, a common practice to compensate for the inefficiency of poorly mixed defoamer.

It prevents the accumulation of dirt and tacky deposits, reducing washing needs and extending the lifespan of machine fabrics. It also prevents the negative impacts that too much defoamer has on the performance of sizing agents, retention aids, and dry strength agents, in this way optimizing the effectiveness of all additives, leading to a 50% reduction in consumption.

Mill results

Release paper mill, Europe

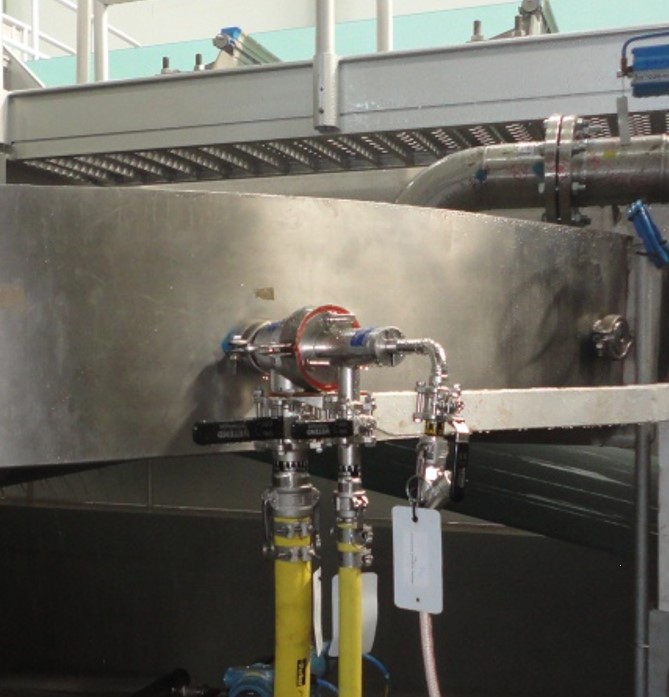

Defoaming agent mixing into a white water tray

- 50% chemical savings

- Foam build-up and gas volume in control

- No chemical overdosing

- Faster response on adjustments

- Cleaner process

- Injection with circulated white water

Specialty paper line, Finland

Defoaming agent mixing into white water flumes of a large specialty paper machine

- 40-50% saving of defoamer

- Hydrophobic sizing; Cobb value improved by 10%

- Cleaner process

Coated fine paper mill, China

Air control in PM approach flow system

- Foam amount reduced to a minimum

- Improved dewatering stability on wire section

- Reduced sheet breaks

- Reduced chemical consumption

- More stable process with TrumpJet

Good mixing of defoamer stabilized the de-aerator surface level removing the pulsation from pumps.

Color index:

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.