TrumpJet® Flash Mixing

Injection mixing of chemicals and additives improves quality, efficiency and sustainability

TrumpJet Flash Mixing is an advanced injection technology for mixing various chemicals and additives into large volume process streams in a fast, effective and uniform way. Mainly used in paper/board production, it saves water, energy and chemicals, and improves machine runnability and paper quality.

TrumpJet for efficient and sustainable paper production

100%

fresh water savings

Significant

energy savings

20-60%

chemical savings

Benefits of TrumpJet Flash Mixing for paper production

substantial

resource savings

- Water savings 100%

- Chemical savings 20-60% (and even more)

- Energy savings

- Less wastewater

- Reduction of CO2 emissions

- Lower production costs

- Quick return on the investment

IncreaseD

production efficiency

Better

end product quality

- Better formation

- Fewer defects

- Uniform sheet structure and profiles

- New product characteristics

- Specialty fibers

“We got excellent results with the TrumpJet Flash Mixing. Better machine total efficiency, and reduced chemical, energy and water consumption.”

“Good mixing and reduced optimal chemical flow impacts positively on the paper formation and paper structure.”

Hartmut Schreck

Production Engineer, SAPPI Stockstadt Mill

See more mill results

For paper, board and tissue, for all grades and capacities

Individual chemical mixing solutions for maximum performance

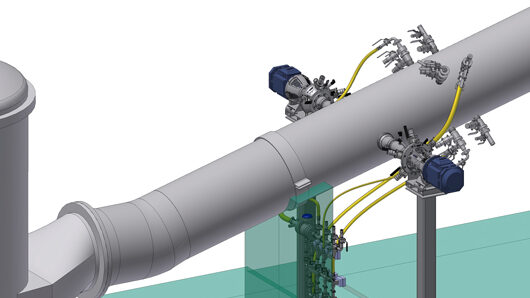

TrumpJet product family includes 7 different mixers and many specialized nozzles. Depending on your production line specifics, our experts will offer you the most suitable and most efficient solution.

Typical chemicals

- Retention aid polymers

- Starch

- Sizing agents

- Micro- and nanoparticles

- Strength chemicals

- Filler

- Dyes and pigments

- Defoaming agent

- MFC, NFC

- Specialty fibers

Chemicals can be added in premixed groups.

TrumpJet Flash Mixing technical features

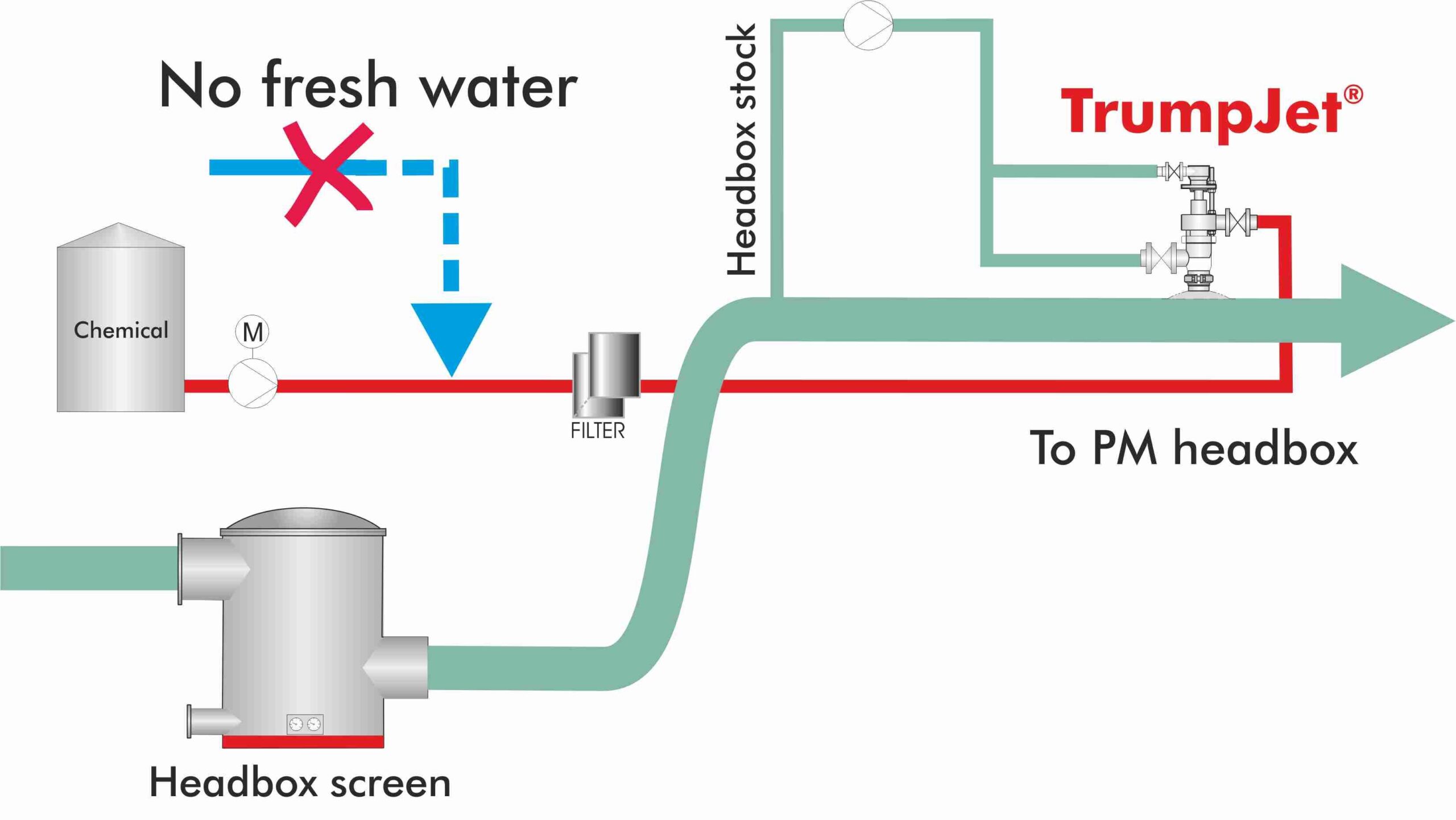

Injection of chemicals using part of the process stream

Instead of fresh water or clear filtrate, injection liquid is a part of the process stream – typically circulated headbox feed stock taken from the initial process flow.

No fresh water has to be added, heated, pumped or cleaned for the purposes of chemical mixing. This leads to significant water and energy savings and reduces production costs, CO2 emissions, wastewater, and overall environmental impact.

Optimal mixing location for maximum efficiency

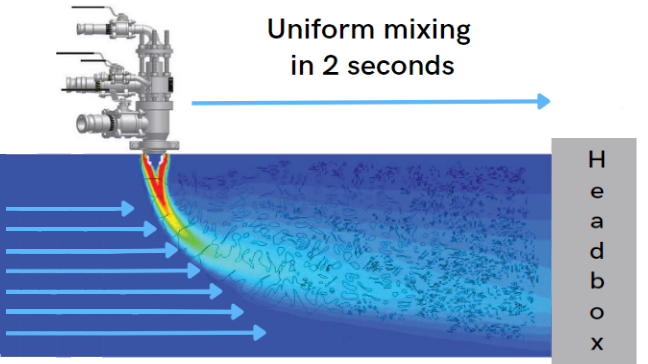

TrumpJet® injects chemicals with a high speed, large open area liquid jet. It quickly disperses chemicals into tiny droplets that react uniformly with process media.

Homogeneous mixing across the entire volume within 2 seconds allows chemical dosing just a few meters before the headbox, optimizing chemical effect while minimizing chemical consumption. It also improves paper formation and end product quality.

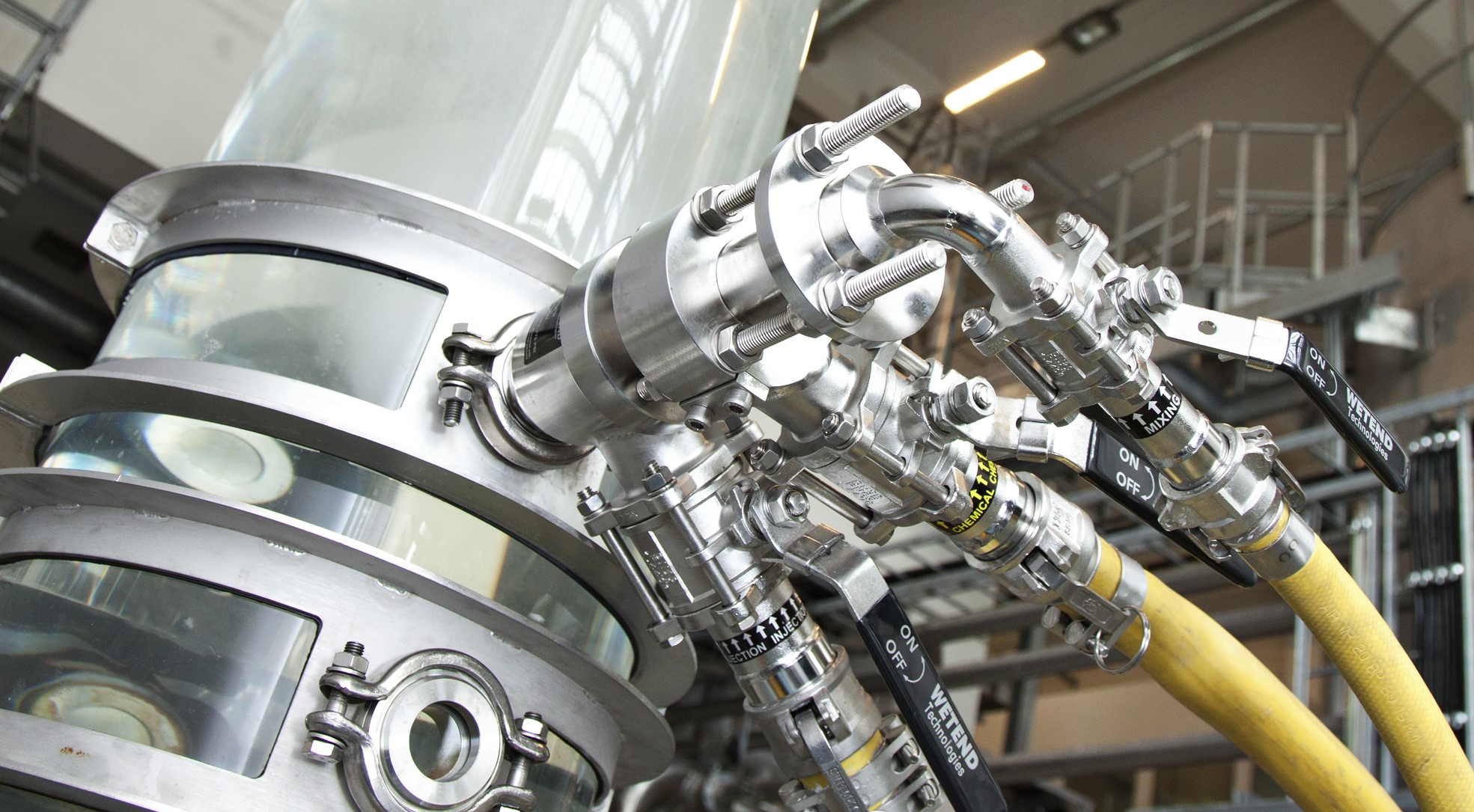

TrumpJet Flash Mixing Reactor for multiple additives

TrumpJet Flash Mixing Reactor enables mixing various chemicals, even with opposing charges, very close to one another in a compact reactor zone located just before the headbox. The result is excellent chemical distribution and dispersion, fast control response, a cleaner process and improved machine runnability.

Uniform mixing and optimized chemical dosing location reduces chemical consumption typically by 20-60%.

“Your TrumpJet technology pretty much revolutionized the way everyone thinks about additive injection systems.”

Larry Montague

President of TAPPI

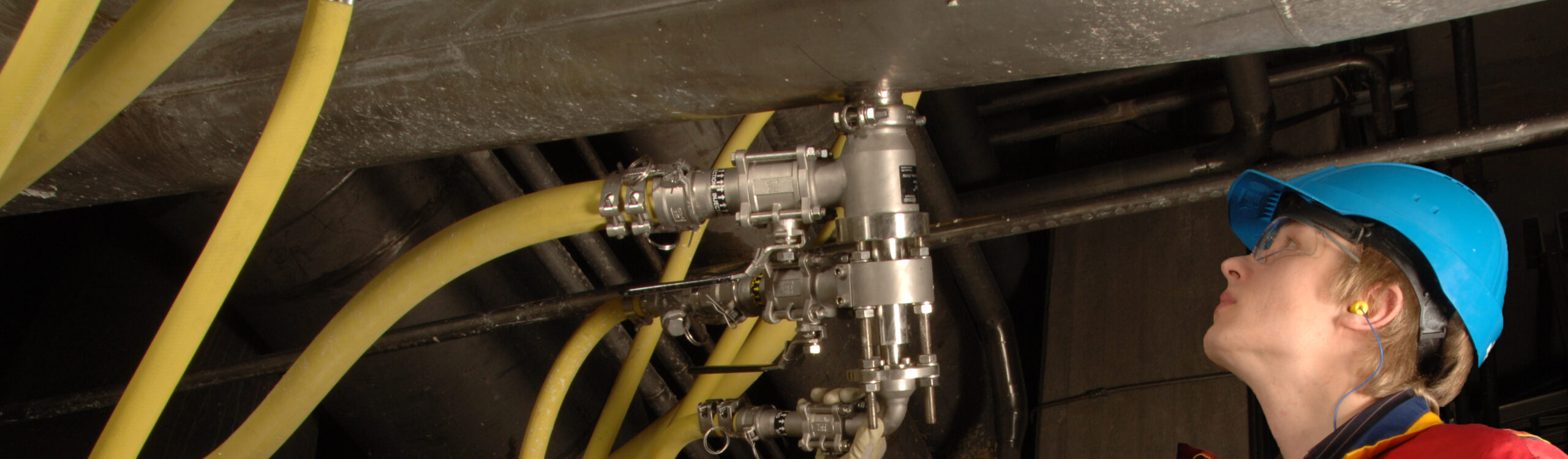

Cleanliness of the chemical feed system is a must

All components of the TrumpJet injection and chemical feed systems are meticulously designed, engineered, and manufactured to prevent scaling, fiber spinning, and the formation of chemical, filler, and fiber lumps.

All joints are flush fitted and all surfaces are polished and electropolished to avoid the formation of harmful dirt deposits.

TrumpJet® hygienic injection pump for excellent runnability

Fast, homogeneous, resource-efficient chemical mixing with TrumpJet

The products of Wetend Technologies Ltd are protected with numerous international patents and patent applications.

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.