Sustainability

Resource efficiency in mind

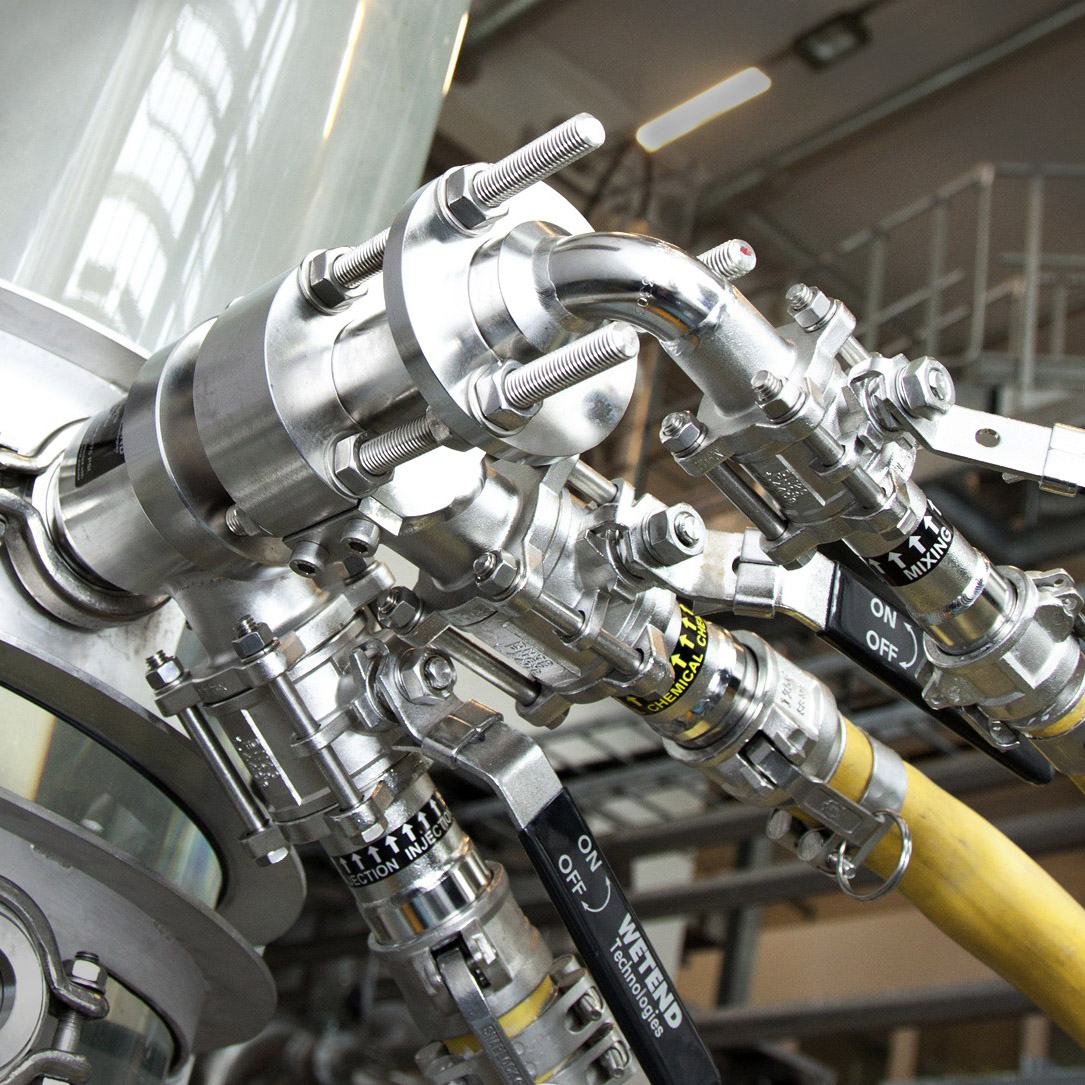

TrumpJet® was invented with a clear purpose – to save water. The new technology not only achieved its goal, but also brought many additional benefits: substantial savings of energy and chemicals, as well as improvement of machine runnability and end product quality.

We help you to achieve your sustainability goals

Our technologies preserve valuable natural resources and enhance sustainability in paper production. With TrumpJet®, you can eliminate the use of fresh water for chemical post-dilution (typically 10-18% of a paper mill’s total water consumption), along with the associated heating costs and CO2 emissions. In addition, chemical savings of 20-60% reduce the environmental impact of your production.

Sustainability is our promise to both our clients and the planet

Our vision extends beyond mere efficiency gains. We firmly believe that by making paper production more efficient, we contribute to a greener and more environmentally responsible future. For paper to be a sustainable choice, it must be the result of a sustainable process.

Resource savings by TrumpJet® mixing stations installed worldwide

120 million m3

annual fresh water savings

3 million kWh

annual energy savings

4 million tons

annual reduction of CO2 emissions

Our clients are greener with TrumpJet®

NewPage Wisconsin Rapids PM16, USA

- Fresh water savings 300,000 m³/a

- Energy savings 14,650 MWh/a

- CO2 emission reduction 2,750 tons/a

- Savings of retention aids 33-43%

SAPPI Stockstadt Mill, PM1, Germany

- 91% fresh water savings

- 69% lower energy consumption

- 18% lower chemical demand

You may be also interested in

Considering chemical mixing optimization?

We can help you to lower production costs, improve machine runnability and product quality, while reducing the environmental impact of your production, and much more.